Bar Bending Tolerances

Minimum scheduling radii, former diameters and bend allowances

|

||||

|---|---|---|---|---|

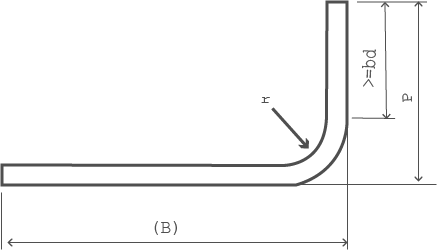

| Nominal Size of Bar, d (mm)* | Minimum Radius for Scheduling, r (mm) | Minimum diameter of bending former, M (mm) | Minimum End Projection, P | |

| General (min 5 d straight), including links where bend >= 150deg (mm) | Links where bend < 150 deg (min 10d straight) (mm) | |||

| 6 | 12 | 24 | 110 | 110 |

| 8 | 16 | 32 | 115 | 115 |

| 10 | 20 | 40 | 120 | 130 |

| 12 | 24 | 48 | 125 | 160 |

| 16 | 32 | 64 | 130 | 210 |

| 20 | 70 | 140 | 190 | 290 |

| 25 | 87 | 175 | 240 | 365 |

| 32 | 112 | 224 | 305 | 465 |

| 40 | 140 | 280 | 380 | 580 |

| 50 | 175 | 350 | 475 | 725 |

| *The minimum end projections for smaller bars is governed by the practicalities of bending bars. | ||||

| NOTE 1: Due to "spring back" the actual radius of bend will be slightly greater than half the diameter of former. | ||||

| NOTE 2: BS 4449:2005 grade B500A in sizes below 8 mm does not conform to BS EN 1992-1.1:2004. | ||||

Tolerances on Cutting and Bending Dimensions

The tolerances for cutting and/or bending dimensions shall be in accordance with the table below and shall be taken into account when completing the schedule. The end anchorage or the dimension in parenthesis in the shape codes specified on Typical Bend Shapes shall be used to allow for any permissible deviations resulting from cutting and bending.

| Cutting and Bending Processes | Tolerance (mm) |

|---|---|

| Cutting / Bending: | |

| Cutting of straight lengths (including reinforcement for subsequent bending) | +25, -25 |

| Bending: | |

| ≤ 1000mm | +5, -5 |

| > 1000mm to ≤ 2000mm | +5, -10 |

| > 2000mm | +5, -25 |

| Length of Bar in Fabric: | |

| +25, -25, or 0.5% of the length (whichever is greater) | |

| Tolerances for shape code 01, stock lengths, shall be subject to the relevant product standard, e.g. BS 4449:2005. | |